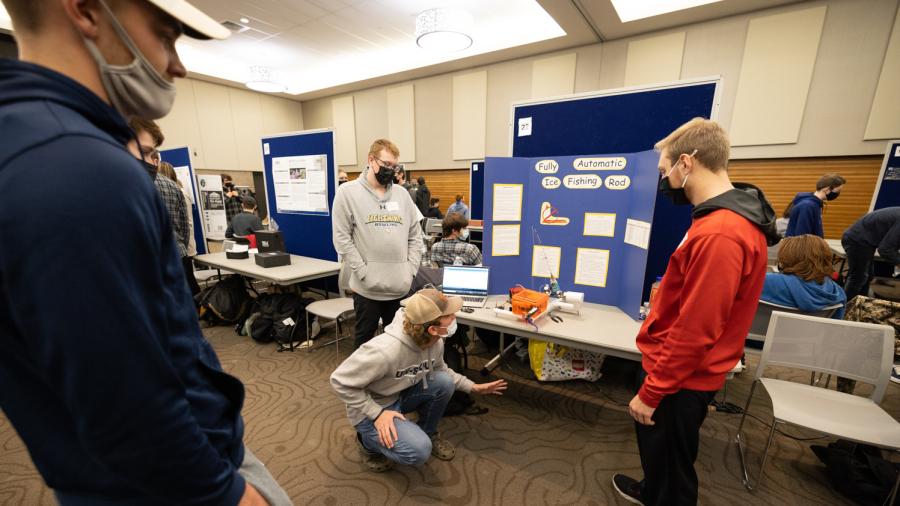

A team of University of Wisconsin-Stout students was hoping for colder weather and thicker ice on area lakes so they could try out their Engineering Technology 100 class creation, a fully automated ice fishing rod.

The students demonstrated their invention at the STEMM Student Expo on Dec. 9.

The rod and reel uses a battery-driven motor to jig, which helps attract fish. Once a fish strikes, the rod automatically hooks the fish and reels it in. Users do have to bait their hooks and remove their catch.

“We were struggling with an idea. We found out a good many of us like fishing and decided, ‘How about a rod and reel for fishing?” said Reimer, a first-year mechanical engineering major from Manitowoc. “We haven’t had an opportunity to try it outside because there isn’t enough ice on the lakes. We really did want to go fishing and see if it worked.”

Other members of the team are Elana Showalter, a first-year mechanical engineering major from Northfield, Minn.; Dominic Post, a first-year engineering technology major from Spencer; Johnny Ballinger, a first-year plastics engineering major of Amherst Junction; and Jacob Mueller, a sophomore computer and electrical engineering major from Combined Locks. The device is charged by a 12-volt battery that will run about four hours, depending on temperatures. Team members estimated it could reel in a fish about the size of a bluegill.

Having students talk about their research is exactly the goal of the expo, said Gindy Neidermyer, interim dean of the College of Science, Technology, Engineering, Mathematics and Management.

The expo, at the Memorial Student Center Great Hall and ballrooms, was held in person for the first time since December 2019, allowing students to share their research with faculty, staff, students and visitors. Nearly 100 tables were set up with research posters and projects.

“Our students’ research truly has potential to impact every sector of life,” Neidermyer said. “This live engagement with students and their research is so positive, plus the outstanding work these students are doing is incredible. Having faculty, staff and students walk around to see the research changes the way we think. The interaction is great and allows students, faculty and visitors to share in the advancement of learning an innovation.”

Senior business administration majors Jared Gemeunden and Aaron Holt, who are both graduating Saturday, Dec. 18, and Chase Pierce, a senior business administration major from North Freedom, developed a business plan for an authentic Mexican taco food truck for their entrepreneurship class.

Their goal was to fill a food niche after taverns close for the night in the downtown Eau Claire area.

“I liked the class because we were coming together and working with classmates,” said Gemeunden, of Hudson.

Holt, of Green Bay, agreed. “This class felt super real,” he said. “It’s applicable. We could start the business today.”

Another group of Engineering Technology 100 students developed an automatic, high-capacity can crusher that could be used by restaurants to help recycle.

Members of the team included first-year students Ethan Frits, a manufacturing engineering major from Lake Elmo, Minn.; and mechanical engineering majors Logan Muffick, of Waterford; Tanner Gehl, of Solon Springs; Ayden Veness, of Prescott; and Spencer Holverson, of Spring Green.

“We spent zero dollars making this model,” Muffick said. “We fabricated a lot of it or found it.”

Students made the metal can crusher and also plastic-molded the gear.

The can crusher takes empty soda cans and feeds them up a gear, where they are put into a channel, crushed and dropped in a recycling bin. The students displayed a partial working concept of the crusher at the expo, using an air compressor to crush the cans.

Muffick said he liked the project. “I enjoyed the learning and the building,” he said. “We all worked together and learned the engineering process.”

The team worked about 150 hours on the crusher.

“It was very much a group project,” Frits said.

CSTEMM offers 20 undergraduate programs and 10 graduate programs.